Innovation Meets Sustainability:

Done Filters' Cutting-Edge Car Filters for a Greener Future

Joining the power of advanced AI and Big Data with car filters industry expertise, DoneFilters optimizes manufacturing by bringing production closer to clients. Results? Reduced lead time. Cost optimization. Minimized environmental impact. Join the revolution with DoneFilters and discover a new era of car filter manufacturing.

Why Done Filters?

Choose Done Filters for unparalleled innovation, sustainability, and financial efficiency in the car filter industry.

Innovation

Welcome innovation in your company with our cutting-edge AI and big data solutions. At Done Filters we combine our domain knowledge of the filter industry with the latest technology. We analyze each order considering many factors to provide our clients with the best products on the best terms.

Sustainability

Reduce your organization’s carbon footprint by ordering filters from local factories. At Done Filters we operate globally and strive to reduce the environmental impact of our clients’ operations by reducing the need for long-distance shipping. Also, we make sure our partner factories follow strict environmental standards.

Financial Efficiency

Cost optimization is vital to every business. At Done Filters we understand it very well. That’s why our systems analyze not only manufacturing costs, applicable taxes, fees, and transportation costs. With Done Filters you can be confident to receive the best possible offer.

Unlock Efficiency and Cost Savings with Done Filters

How Are We Different?

How Is It Possible?

Can Done Filters Benefit My Organization?

Customization

Our experience in the car filter industry lets us take care of every order. At Done Filters we recognize the diverse filter needs of different vehicles; that’s why our process allows a high degree of customization.

Global Operations

Our innovative solution only makes sense if we operate globally. We formed partnerships with factories around the world to make sure we can provide services to any organization interested in revolutionizing its supply chain.

White Label

Although we are proud of our brand, we are happy to supply white-label products. We believe in revolutionizing the manufacturing process and making it more sustainable. In such a mission label is insignificant.

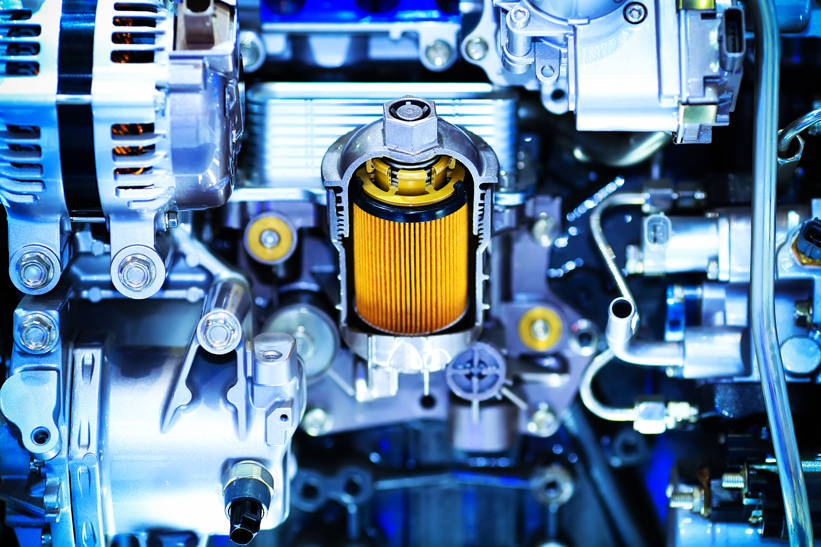

Done Filters Laboratory

With our fully equipped in-house laboratory run by certified experts, we can guarantee the quality of our products.

Tests and Reports

We do comparison tests for all types of filters. We also perform filtration media tests to make sure we provide our clients with the best quality. We provide comparison test reports for filters adhering to ISO standard procedures. All tests are performed in the original filter housing or a universal housing.

Experts

Done Filters laboratory is run by a skillful and experienced team of engineers trained and accredited in international courses. We carefully recruit them and provide them with the best possible equipment to be sure our tests are 100% reliable.

Equipment

Done Filters laboratory runs on state-of-the-art equipment regularly calibrated and controlled by a registered institute. We are confident that the combination of the expertise of the testing team with reliable equipment makes our test a trusted source of information about different filters' performance.

Main Filter Categories * Please Click each one below to see details*

Choose from more than 840 fuel filters in our catalog.

Done Filters offers fuel petrol and diesel filters with metal or plastic body and ecological elements. We also produce filter cartridges in different technologies and shapes to meet different engine and fuel system requirements.

Choose from more than 360 transmission filters in our catalog.

Done Filters offers transmission filters with metal or plastic body in different technologies and shapes. We are able to meet all kinds of requirements for different transmission oil systems.

Choose from more than 2060 air filters in our catalog.

Done Filters offers air filters in various shapes and technologies (polyurethane injection, polypropylene injection). We are able to meet all kinds of different engine requirements.

Choose from more than 800 cabin filters in our catalog.

DoneFilters offers cabin filters with metal or plastic body and ecological elements. We also produce filter cartridges in different technologies (polyurethane injection, with non-woven, paper, or active carbon media) and shapes to meet different cabin air system requirements.

Choose from more than 40 oil filters in our catalog.

Done Filters offers oil filters with metal or plastic body and ecological elements. We also produce filter cartridges in different technologies and shapes to meet different engine oil system requirements.

How It Works?

Once we receive the order, we run it through our advanced AI- and big data-powered tools to find the optimal solution. We consider factors like the client's location, applicable taxes, logistics, and, most importantly, any special order requirements.<br><br> We aim to find the option that matches the specified requirements at the lowest cost, shortest lead time, and the lowest carbon footprint.<br><br> Needless to say, each of those factors can be given priority to meet the client’s needs.<br><br> The client receives the best possible offer matching their criteria within two days. They later choose between our Done Filters brand or the white label option.

Get in touch with us

© 2023 Done Filters | All Rights Reserved